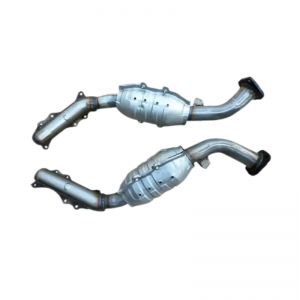

Ford Transit Connect Catalytic Converter 2.0L 4cyl 2010-2013 BANK1

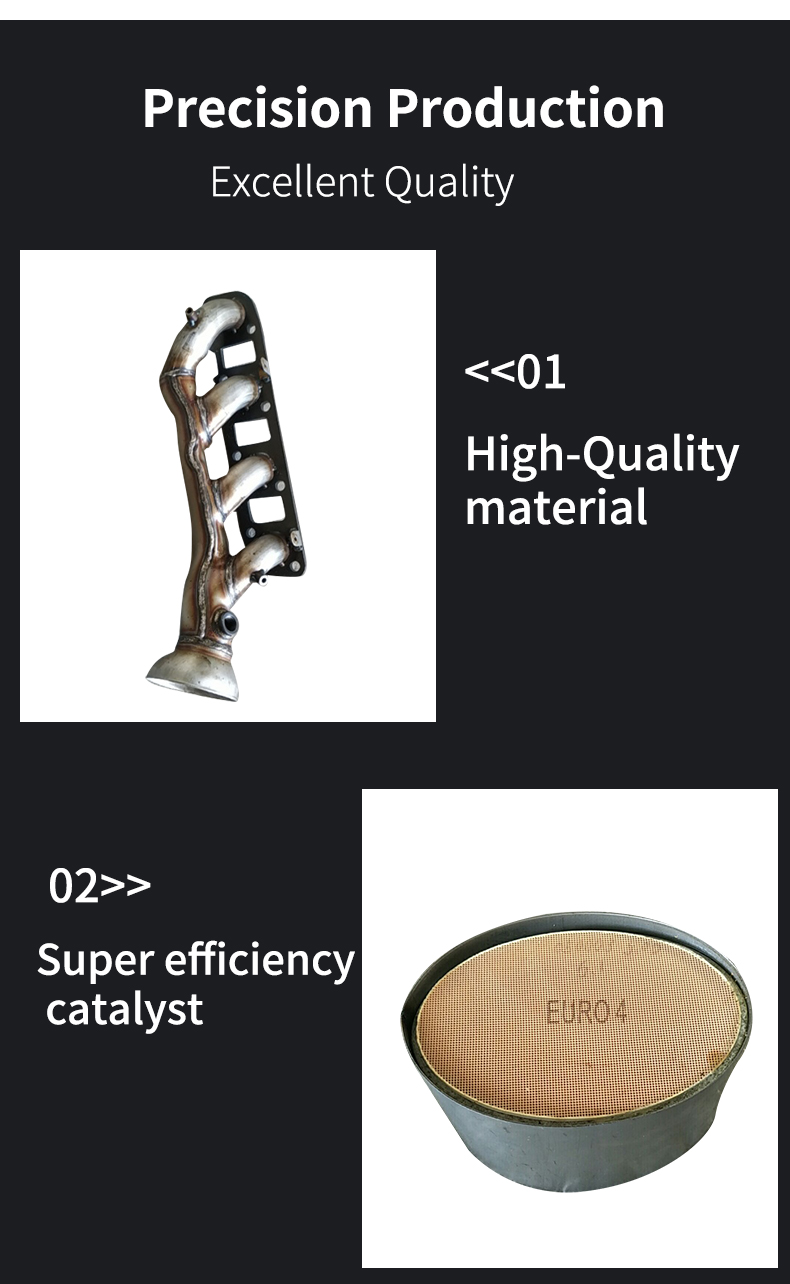

The main component of ceramic carrier is cordierite, which is usually extruded, dried and sintered at high temperature using ceramic materials. The ceramic carrier is a honeycomb-like entity when viewed from the cross-section, and the wall thickness is very thin. The purpose is to try to make full use of the existing volume to increase the chemical reaction area of the catalyst reaction bed, and also to prevent thermal degradation of the catalyst. In order to allow the catalytic converter gas flow to have a larger surface flow area, the carrier is usually made into a honeycomb shape with very thin wall thickness to make full use of the limited space. At present, the main product specifications mostly use 400 mesh (400 holes/square inch) or 600 mesh (600 holes/square inch) ceramic honeycomb carrier. During the extrusion process, a large number of thin-walled, parallel, usually square channels are generated.

| Carfitment | ||||

| OE NO. | Car Fitment: | Mold | Year: | |

| - | Ford Transit | 2.0L 4cyl | 2010-2013 | |

| Product name | Ford Transit | |||

| Model Number | DJN808 | |||

| Brand Name | DJN | |||

| Emission Standard: | EURO 2/3/4/5 | |||

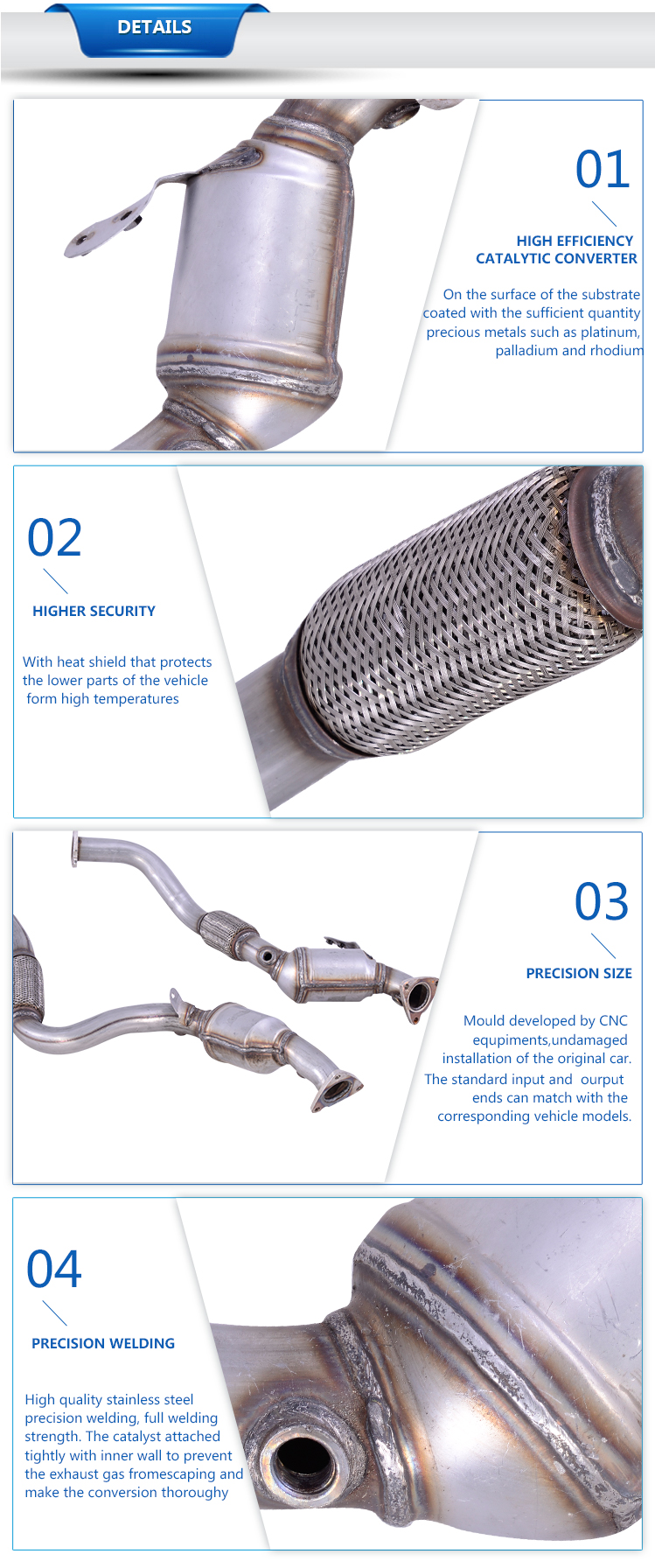

| Material | Inside : ceramic(honeycomb) substrate 400cpsi with mat | |||

| Shell :304 or 409 # stainless steel shell,stainless steel pipe | ||||

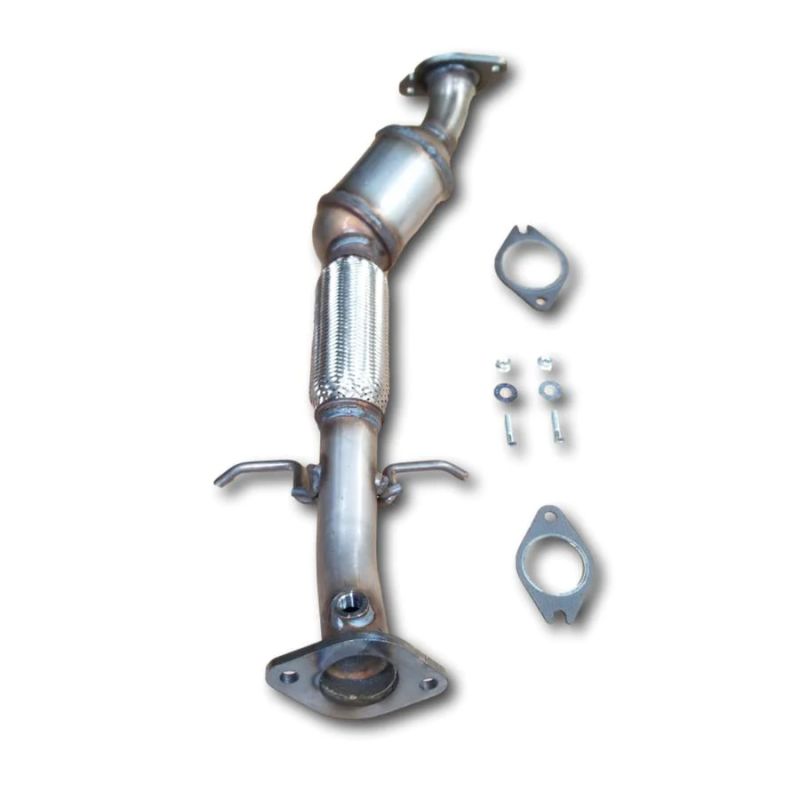

| Oxygen sensor ports | Yes | |||

| cpsi | 400 /600/800 | |||

| Wall thickness | 0.09±0.025 | |||

| Warranty | 30000 miles performance/2 years | |||

| Packaging: | Air bubble film and Carton Packing | |||

| MOQ: | 50 pcs | |||

| Supply Ability | 1000 Piece/Pieces per Week | |||

| Place of Origin: | Jiangsu | |||

| SAMPLE ORDER: | Accept | |||

| Condition | new | |||

| Function | reduce harmful emission (CO,HC,NO) from motor vehicle Over 95% conversion efficiency; | |||

| Service | Customers' specific demands available, design drawings are welcomed. OEM service is accepted | |||

| Supply Ability | 1000 Piece/Pieces per Month | |||

| Packaging & delivery | Air bubble film and Carton Packing, inside fix the product decently with expanded material | |||

| Port | Shanghai/Ningbo | |||

| Lead time: | 10-30 days . | |||

| Active catalyst ingredients | Pt, Pd, Rh, and rare earth elements | |||

| Shape | round, oval, race track | |||

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat

-

Top