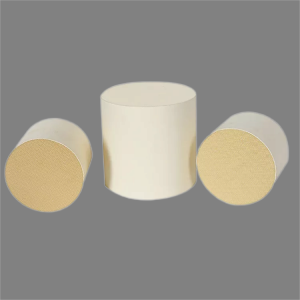

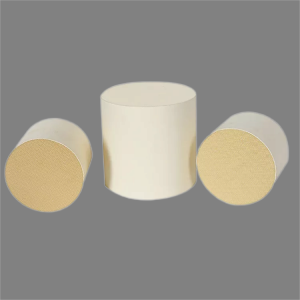

Ceramitic Honeycomb Substrate

-

Hot -sale Cordierite Honeycomb Ceramic Substrate For Catalytic Converter

Properties

Environmentally friendly ceramics Ceramic materials can be widely used in various environmental protection fields due to their high strength, high-temperature, corrosion, and wear resistance, such as automobile exhaust emissions

-

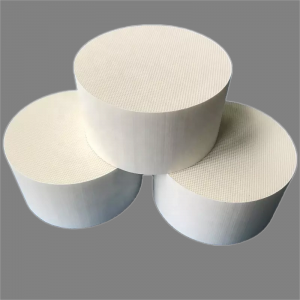

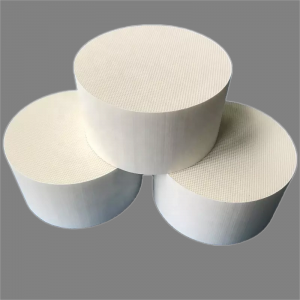

Industrial ceramic honeycomb SCR catalyst ceramic monolith

product functions:

1. Fast warming up

2. Low exhaust resistance

3. Superior compressive strength

4. Stable water absorption performance

5. Accurate dimensions for perfect assembling

6. Perfect compatible with the active components of the catalyst

product functions:

1. Fast warming up

2. Low exhaust resistance

3. Superior compressive strength

4. Stable water absorption performance

5. Accurate dimensions for perfect assembling

6. Perfect compatible with the active components of the catalyst

-

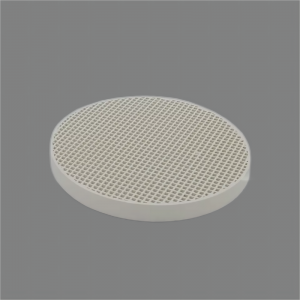

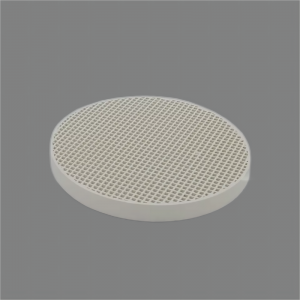

China Professional Manufacture Cordierite Honeycomb Ceramic Catalyst Substrate For Catalytic Converter

Material

Honeycomb ceramics can be made from a variety of materials. The primary materials are cordite, cellulite, aluminum titan ate, activated carbon, silicon carbide, activated alumina, zircon, silicon denitrify, cordierite-mullite, cordierite-aluminum titan ate, and other composite substrates

-

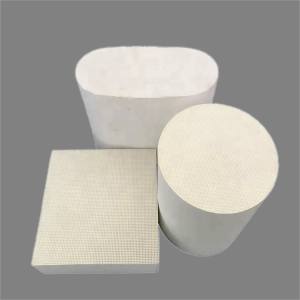

ceramic honeycomb gas heater ceramic honeycomb substrate

More details:

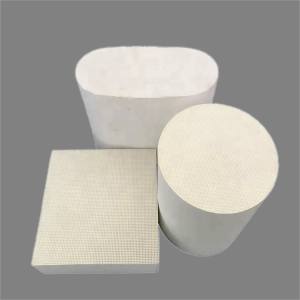

The main products include cordierite honeycomb ceramic bricks for RTO& RCO, ceramic substrates for DOC, DPF, SCR and infrared honeycomb ceramic burning plate for gas stove. We focus on providing cost effective solutions to waste and gas treatment, environmental protection, household heating appliances etc.

With strict quality control and our best service, the products have been sold well on the domestic market and exported to many countries in North America, Europe, Middle East, South East Asia, etc.

Our mission is “Quality, Value and Innovation”. We look forward to a long-term business relationship with you

-

ceramic honeycomb gas heater ceramic honeycomb substrate

Advanced Ceramics Features

1) A variety of specifications available

2) Satisfy various technical request

3) 3) Lower medium spoilage

4) Good insulation performance

5) High strength

6) Wear resistant performance

7) High density

8) refractory and high temperature resistance

-

Ceramic Substrate To provide customized services Honeycomb Ceramic Substrate

1. Thin wall, high surface area.

2. Low coefficient of thermal expansion.

3. Low back pressure, and good air flow.

4. Good thermal shock resistance and heat resistance.

5. High compressive strength.

6. Stable water absorption rate.

7. Accurate size control, good for encapsulation.

8. Ideal matching with different catalysts

-

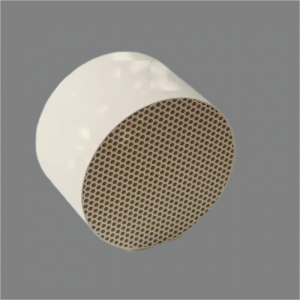

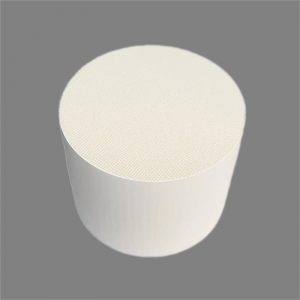

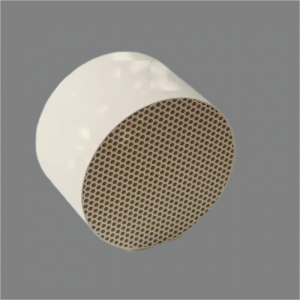

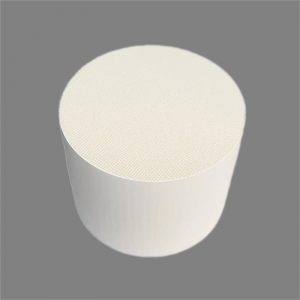

Car Catalyst – Ceramic Honeycomb 200-600cpsi Main Features /Advantages of our substrates

Thin hole wall, large specific surface area, low resistance, low bulk density, and high

compressive strength;

Small thermal expansion coefficient;

Excellent thermal shock resistance performance;

Good compatibility with various catalyst active components

Good cold start performance, low light-off temperature, fast heating, low gas resistance

and high conversion efficiency;

it can be designed into a cylindrical, racetrack and other special-shaped structures according

to different motor vehicle requirements;

The product meets the requirements of various types of motor vehicles and their

supporting requirements

-

High-Quality Ceramic Catalytic Converter / Honeycomb Ceramic Substrate for Exhaust Car/Heavy Truck

Application of catalytic converter ceramic substrates:

* Substrate for gasoline/petrol fuel engine exhausting system

* Substrate for diesel fuel engine exhausting system

* Substrate for air filtering;

* Substrate coated with precious metal (palladium, platinum, and rhodium) to make a catalytic converter. It removes harmful

chemicals from automobile exhaust purification systems, such as HC, CO, and NOX. It can meet Euro I, Euro II, Euro III, Euro IV, and Euro V standard

-

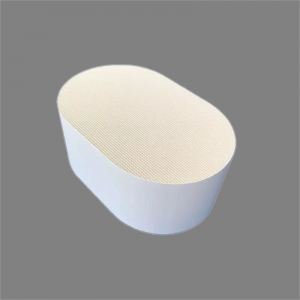

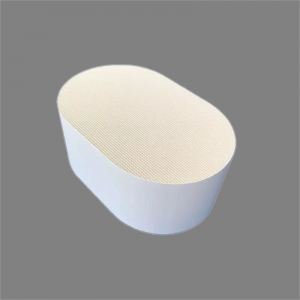

Hot Sale Universal 120*80*50*Ceramic Honeycomb Catalytic Converter DOC Substrate

1. We supply worldwide: North American, South American, Europe, Australia, Southeast Asian and Mid-East

2. Professional manufacturer of catalyst coating

3. Sample: According to your request, sampling time 3-7day. For existing samples, sampling time 1-2days

4. OEM accepted: We can produce according to your request

-

Euro2.3.4.5 standard honeycomb ceramic substrate

Honeycomb ceramic is used as DOC, SCR and DPF substrate. It features higher cpsi, thin wall and higher specific surface area, etc. After being coated with precious metal, it is applied to diesel and gasoline exhaust system and industrial gas treatment. We make customized production based on your specification